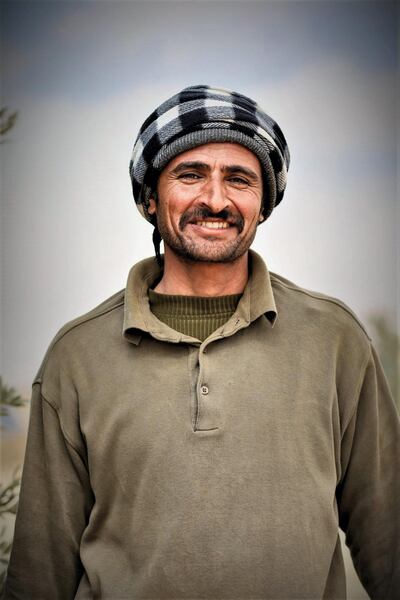

About two hours outside Amman, in the middle of a vast desert, sit 155,000 olive trees. They produce some of the Middle East’s highest quality olive oil, all extra-virgin. Their fruit goes through a high-tech Italian press, and the oil is the result of a decade of research and constant tweaking. The farm is the “fifth child” of Ziad Bilbeisi, former architect and founder of Al Maida. He works with his four “real” children to produce the oil that won a bronze medal at the London International Olive Oil Competition in April last year, where it was up against heavyweights from across the world.

Al Maida olive oil

Twenty years ago, after moving back to Amman from London where he’d been working, Ziad started to make oil with fruit from the 200 or so trees on his land. He realised there was a lack of high-quality extra-virgin olive oil in the Jordanian market, and curiosity and passion drove him to remedy that. Soon, he imported a small press from Italy and began to learn the technicalities that take olive oil from acceptable to extraordinary.

“The more you look into it, the more mysterious it is,” he says. “And the health benefits are enormous.” Olive oil is a key source of antioxidants and monounsaturated fats, which can help prevent heart disease, osteoporosis and type 2 diabetes; and are good for skin and hair. Extra-virgin olive oil has more of these antioxidants and good fats, plus fewer chemicals.

“Olive oil is a huge part of Jordanian culture and food history, but the value of premium extra-virgin olive oil simply isn’t there,” says Firas Bilbeisi, one of Ziad’s sons, who lives in London and works in the sales side of the business. “Most families in Jordan have a few trees, and they’ll go to the local mill and get a few containers for the family, but the quality is poor.”

Changing perceptions

In an effort to change the perception around olive oil in the country, and also because he saw a market opportunity, Ziad purchased a plot of land outside the city about 10 years ago and imported Spanish olive trees. People told him he was crazy, and that he was wasting money.

“Even the Ministry of Agriculture said to me: ‘Do you really believe in this?’” he says. A decade later, he owns four plots of land and Al Maida is the largest family-run estate in Jordan, producing between 56 and 100 tonnes of oil each year, and supplying it to some of Ziad’s previous sceptics.

The Bilbeisis grow Spanish Arbequina and Arbosana trees, Greek Koroneiki olives, and the local varieties Nabali and Baladi. Research led Ziad to a high-intensity growing system, which allows more trees to be planted in an area, and allows them to produce more oil, while also eliminating the gap year most farms have.

As the olives grow, Ziad and his team of about a dozen permanent workers (the number goes up during harvest season, and often includes Syrian refugees) moderate the moisture, wind, radiation and temperature through a weather station. The trees are all tilted at 355 degrees, towards the sun.

“A lot of people think: ‘Oh, I have some trees, I’ll just let them grow and make oil.’ It’s not like that. Not if you want great oil, anyway,” says Amelia, Ziad’s daughter, who works with him in Amman.

Traditional farms are susceptible to weather and irrigation, especially in the middle of the Jordanian desert. However, Ziad’s land sits above artesian wells, which are pumped into reservoirs throughout the farm by solar-powered pumps. He is still subject to daily extraction limits set by the government, but the water is always there and ready.

Quality control

The olives are harvested and pressed within the hour on-site, in a mill from Mori-Tem, a leading Italian manufacturer of olive mills. “Every hour [after harvesting] that they’re not pressed, they deteriorate. This reflects in the final product,” Ziad says. The mill is the same one used by many manufacturers in Europe and the US, and looking out over the trees and back at the machine, you could mistake Al Maida for somewhere in Tuscany.

“We look at what Europe does; that’s our default,” Firas says, explaining that the family stick to European standards rather than less stringent local regulations. The two benchmarks of the International Olive Council (a regulatory agency based in Madrid) are fatty acids and peroxide. In order to be classified as premium-grade olive oil, fatty acids have to be less than 0.8 per cent; Al Maida’s run at 0.2 per cent. Peroxide levels should be under 20; Al Maida’s are under 10. When the team entered the London International Olive Oil Competition, Ziad says it wasn’t so much about recognition as seeing where they stood, so “we know how we can improve”.

Chefs, too, are starting to take notice of Al Maida olive oil. It is currently sold white label to Michelin-starred restaurants in the UK, to restaurants across the Middle East, and to private clients. In the UAE, diners can find Al Maida on Andaz menus. Amelia hopes to expand to the US soon and sell to consumers under the brand’s own label.

Her hope is that discerning consumers will understand the difference between low and high-quality oil. “When you buy in a supermarket, you don’t always know what you’re getting,” Amelia says. “There are buzzwords like ‘cold-pressed’, which doesn’t mean anything because almost all extra-virgin olive oil is pressed cold, but there are numbers you can look for [high-quality olive oils will list their fatty acid and peroxide numbers]. And if consumers can learn to taste, they have the power.”

When it comes to tasting, consumers can start with a few basics: the oil should have an element of tart fruitiness; should cleanse your palate, not stick to it; and should not scratch the back of your throat (that means it’s oxidised). One problem is that people are so used to consuming bad olive oil that sometimes when they do a taste test, that’s what they prefer. “It’s an outdated mentality where premium-grade olive oil is still held in the same regard as any base oil,” Amelia says.

Still, she and her father are hopeful things can change, and they’re continuing to improve their product and educate those who are interested. Changing public perception, learning in-depth technical skills from scratch, producing olive oil in a desert, and working to be among the world’s best producers – it’s a big task, especially for someone approaching 80. But Ziad doesn’t regret going down this path.

“I only wish I started when I was younger,” he says, looking over the trees. “When I see my people enjoying the oil, I feel very happy. It’s lovely to have people appreciate something you’ve made.”